Precision machining

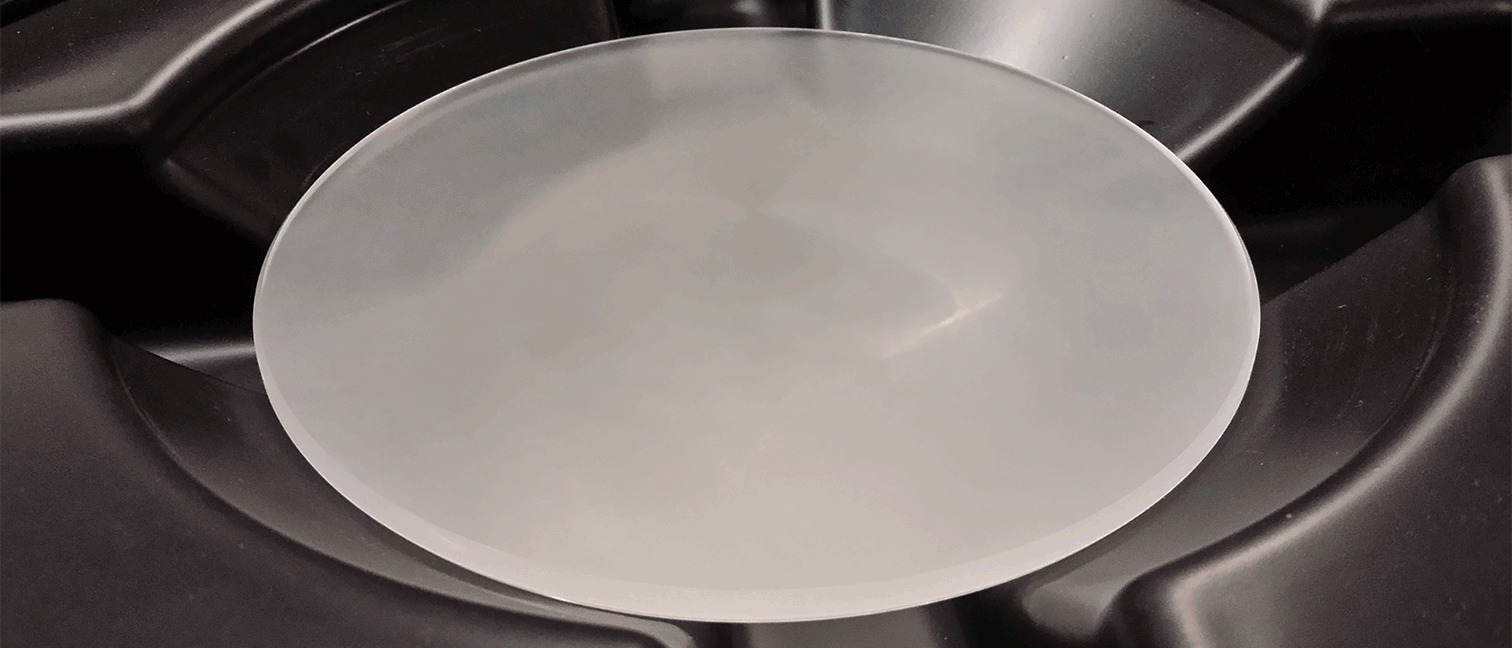

The precision machining of spherical and aspherical optics as well as plano optics takes place in close cooperation with our regional manufacturing partners.

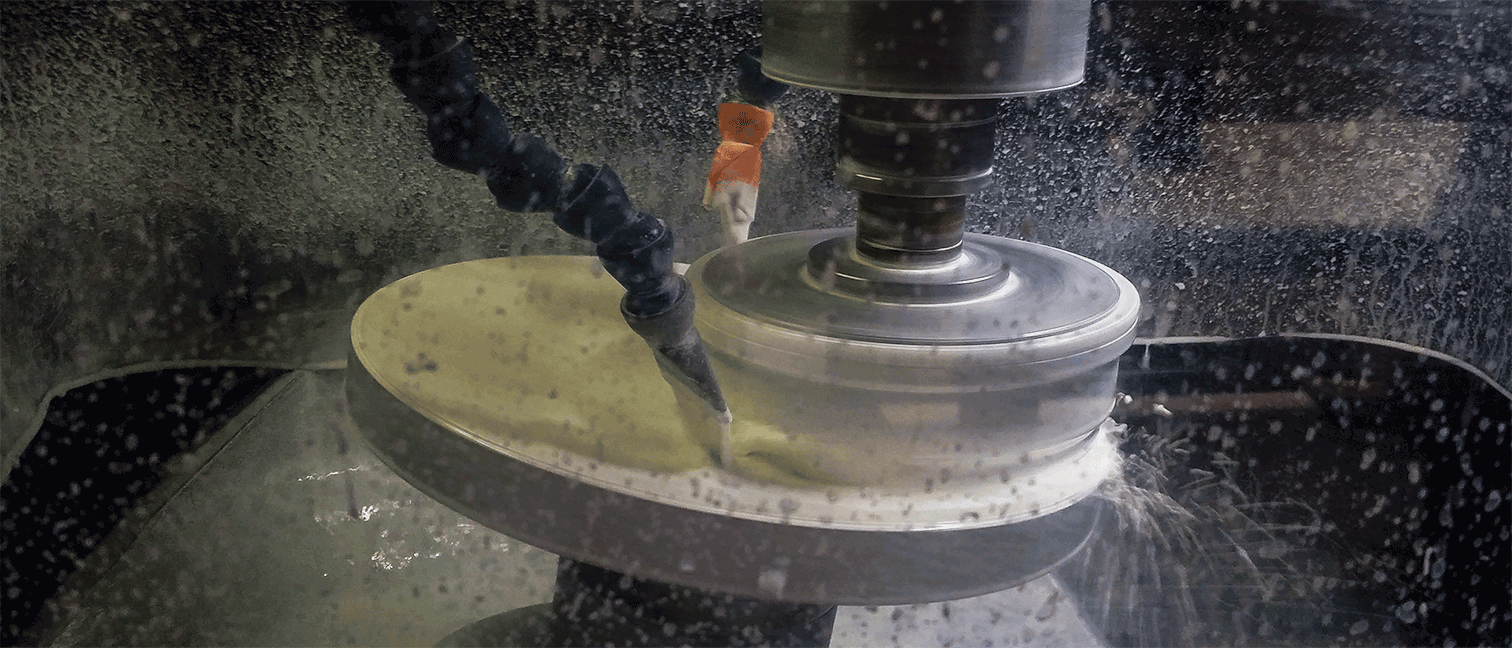

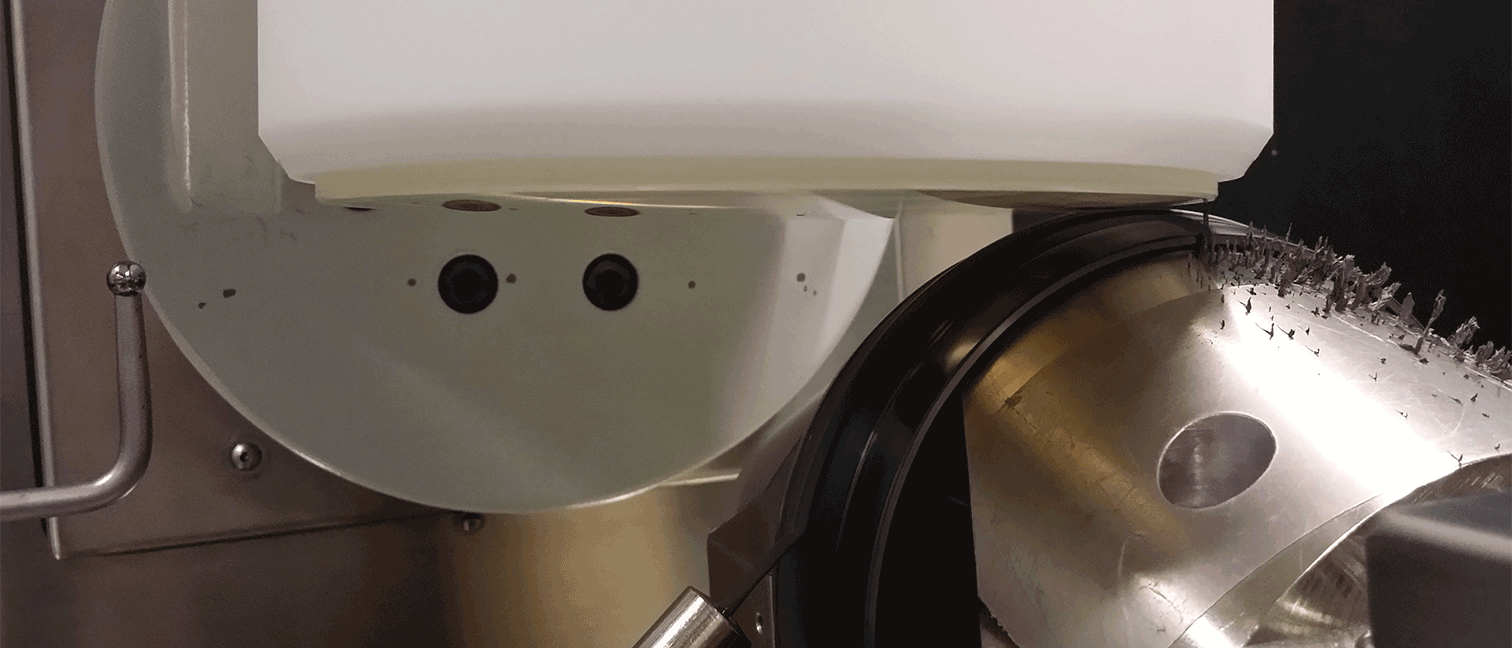

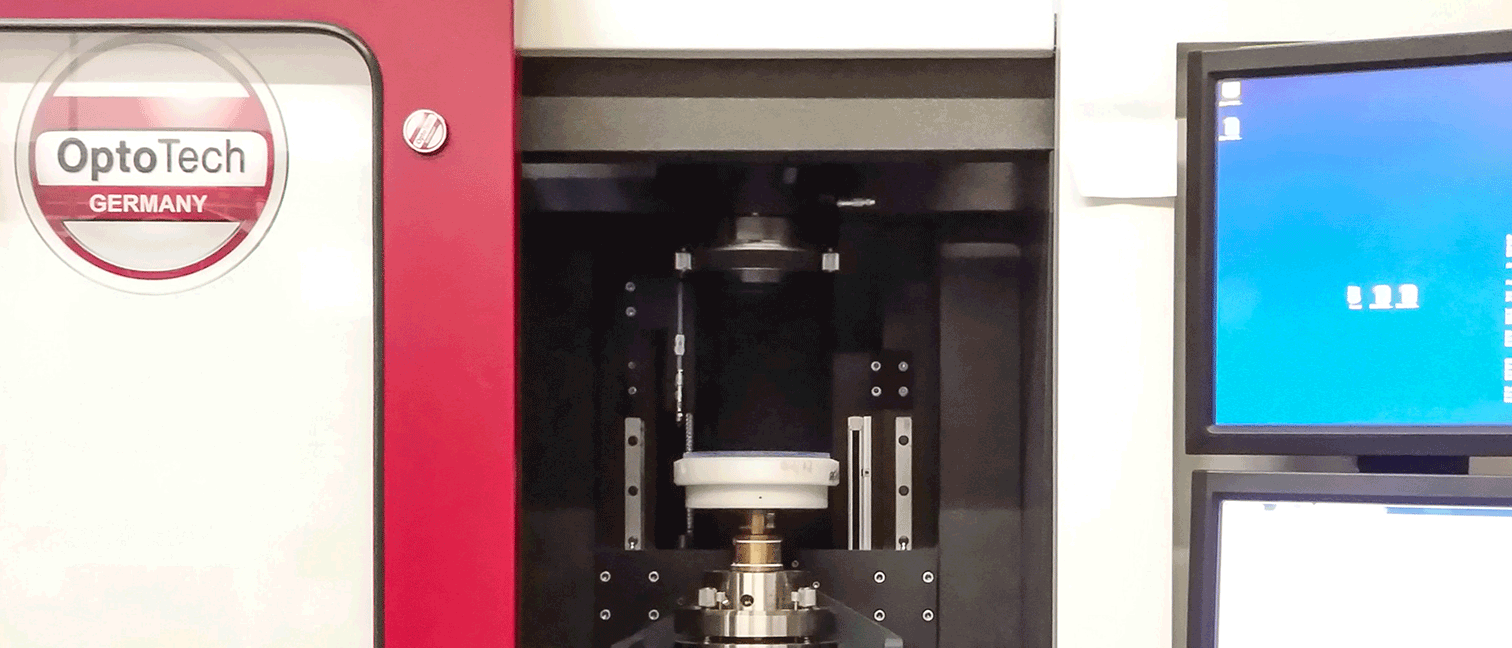

In addition to conventional optical production by means of mechanical and manual production, high-precision CNC machines for pre- and fine grinding, polishing (e.g. OptoTech PPM 301 CNC) and centering are used.

The latest production technologies such as the synchrospeed method and the MRF technology (e.g. QED Q22-X) are also used.

However, these advanced CNC technologies can not replace the knowledge and expertise of a precision optics master with decades of experience in his field.

Measuring and testing technology

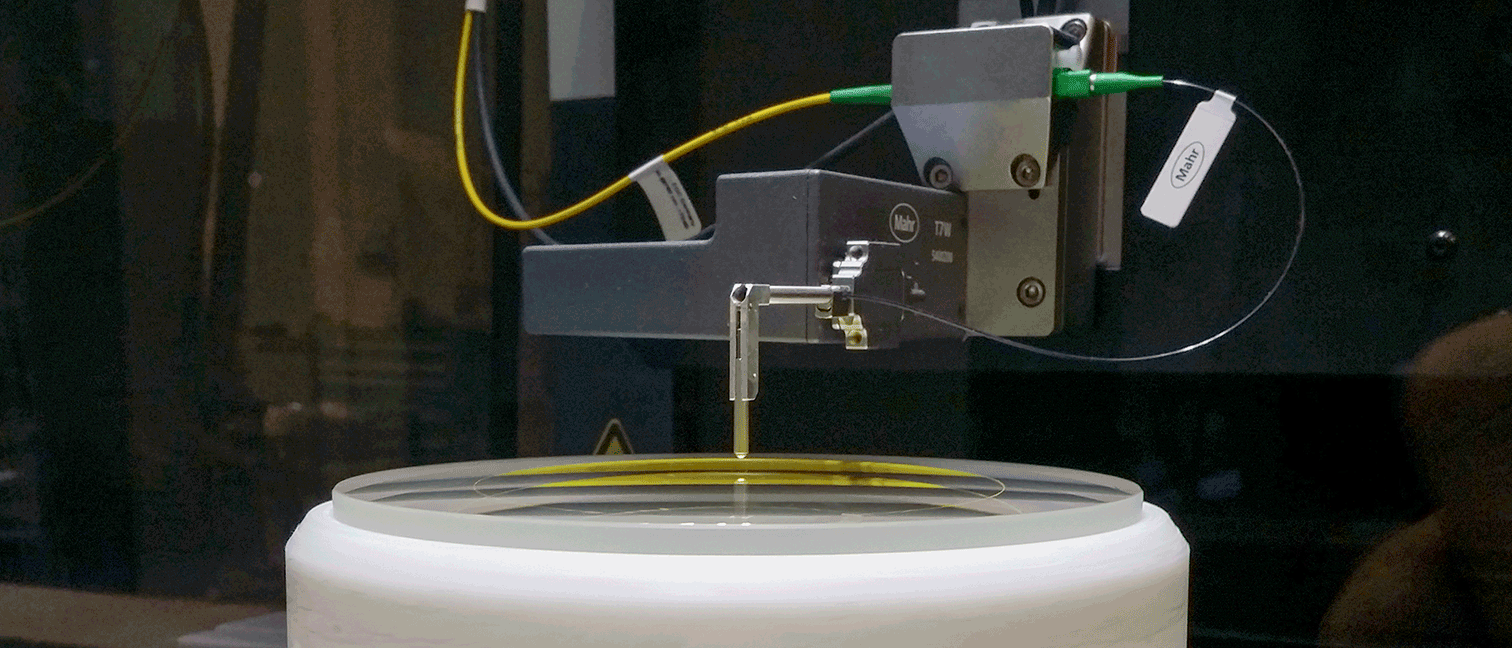

To test the parameters of optical components and systems, various classical testing techniques and test methods using test plates, goniometers, autocollimators, spectrophotometers, laser interferometers, etc. are used.

These are supplemented by state-of-the-art measurement and test technologies such as aspheric stitching interferometer (e.g. OptoTech MSI 300), 3D measurement (e.g. Mahr MarForm MFU 200 Aspheric 3D) and Shack-Hartmann wavefront sensor.

Portfolio

1 Spherical optics

2 Plano optics